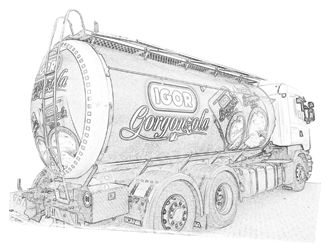

Our journey begins in the uncontaminated pastures of 180 farms in the Piedmont and Lombardy regions, where the cows live a healthy life and are fed only with natural feed completely free of growth hormone(rBGH).

All milk, which, being produced following the specific procedures indicated by IGOR, is of the highest quality, is delivered fresh daily to the milk reception department of the factory.

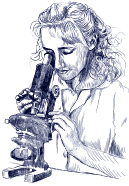

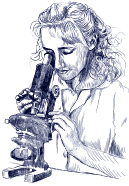

Upon delivery, milk samples undergo stringent tests in the lab unit to determine milk wholesomeness according to well-defined chemical, microbiological, and organoleptic parameters. The raw milk is then stored in vertical insulated silos (tanks) equipped with a constant temperature control system.

All milk is then pasteurized and transferred to the curdling tanks or vats where it is incubated with a mixture of starter, penicillium roqueforti, selected yeasts, and calf rennet. That’s it! These are all the ingredients we need to make Gorgonzola.

IGOR uses exclusively thermophilic bacteria, which guarantee production of a cheese with high organoleptic qualities.

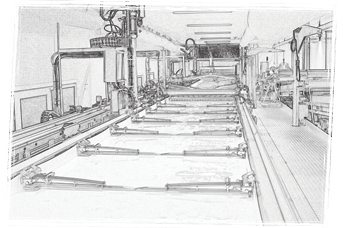

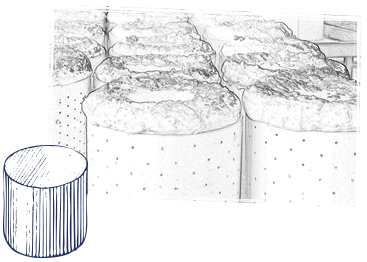

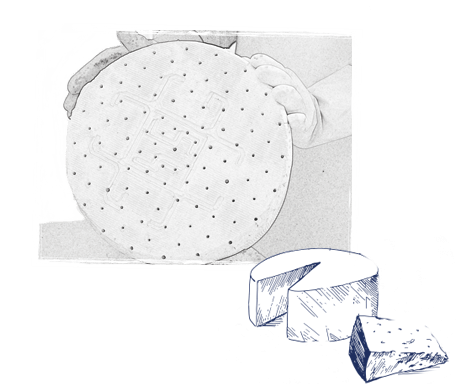

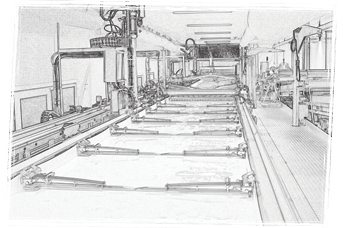

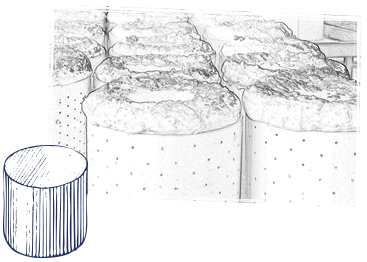

And now, something magical is going to happen: the milk turns into curd. Once the whey in excess is removed, the curd can be diced and poured into stainless steel moulds.

This is how we shape a Gorgonzola wheel.

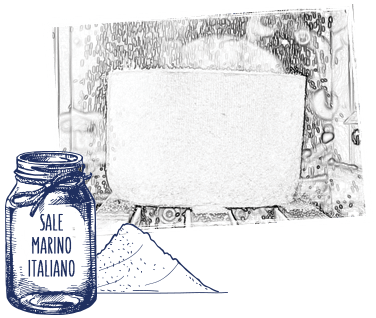

After 24 hours, the Gorgonzola is dry salted for the first time by sprinkling filtered and clean Italian sea salt; Gorgonzola is then placed in a warm room at a temperature of about 21 C°.

Twenty-four hours later, Gorgonzola undergoes a second phase of salting. Depending on which variety of Gorgonzola we are dealing with – sweet or piccante (spicy) –, the storage time in the warm room can vary from two to seven days.

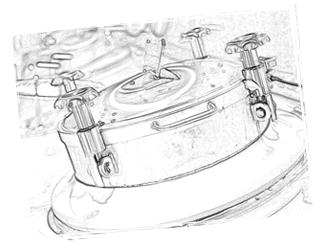

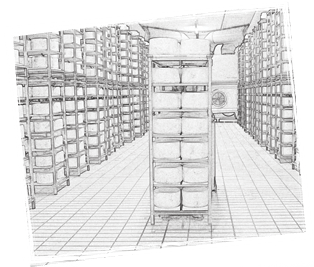

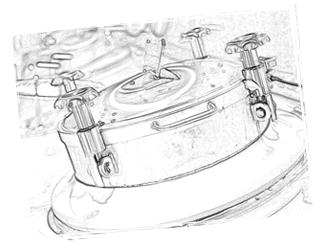

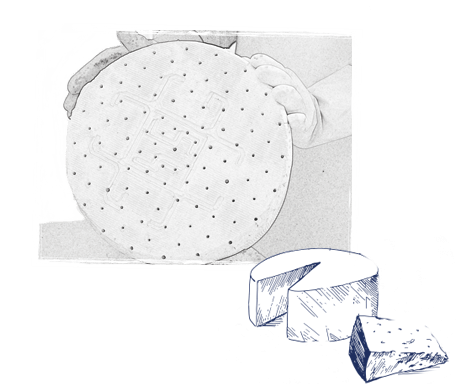

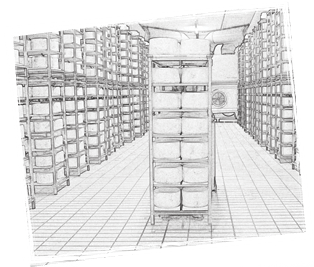

Gorgonzola is then stored in the first ripening room at a temperature of 3-5 C°. Here is subject to punching with steel needles; these holes in the cheese paste promote the development of a blue-green veining, also known as marbling, due to the natural growth of moulds favored by oxygen entering the holes. The wheel is then salted again on the rind.

After 50 days of maturation for the sweet variety and, at least, 80 days for the piccante (spicy) one, our Gorgonzola is finally ready.

Our journey begins in the uncontaminated pastures of 180 farms in the Piedmont and Lombardy regions, where the cows live a healthy life and are fed only with natural feed completely free of growth hormone(rBGH).

All milk, which, being produced following the specific procedures indicated by IGOR, is of the highest quality, is delivered fresh daily to the milk reception department of the factory.

Upon delivery, milk samples undergo stringent tests in the lab unit to determine milk wholesomeness according to well-defined chemical, microbiological, and organoleptic parameters. The raw milk is then stored in vertical insulated silos (tanks) equipped with a constant temperature control system.

All milk is then pasteurized and transferred to the curdling tanks or vats where it is incubated with a mixture of starter, penicillium roqueforti, selected yeasts, and calf rennet. That’s it! These are all the ingredients we need to make Gorgonzola.

IGOR uses exclusively thermophilic bacteria, which guarantee production of a cheese with high organoleptic qualities.

And now, something magical is going to happen: the milk turns into curd. Once the whey in excess is removed, the curd can be diced and poured into stainless steel moulds.

This is how we shape a Gorgonzola wheel.

After 24 hours, the Gorgonzola is dry salted for the first time by sprinkling filtered and clean Italian sea salt; Gorgonzola is then placed in a warm room at a temperature of about 21 C°.

Twenty-four hours later, Gorgonzola undergoes a second phase of salting. Depending on which variety of Gorgonzola we are dealing with – sweet or piccante (spicy) –, the storage time in the warm room can vary from two to seven days.

Gorgonzola is then stored in the first ripening room at a temperature of 3-5 C°. Here is subject to punching with steel needles; these holes in the cheese paste promote the development of a blue-green veining, also known as marbling, due to the natural growth of moulds favored by oxygen entering the holes. The wheel is then salted again on the rind.

After 50 days of maturation for the sweet variety and, at least, 80 days for the piccante (spicy) one, our Gorgonzola is finally ready.